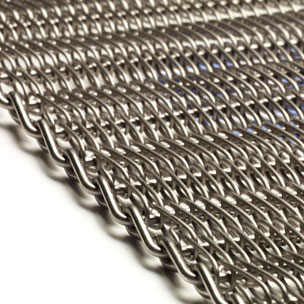

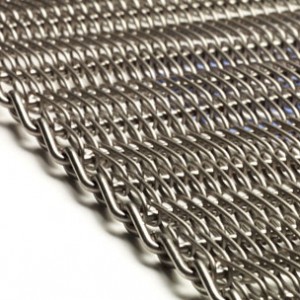

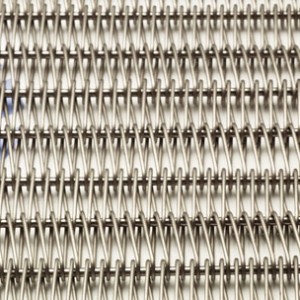

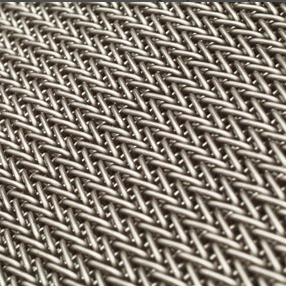

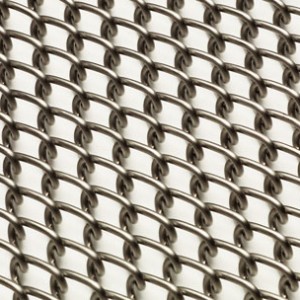

I-Flat Spiral yakhiwe ngokushintshana kwamakhoyili athandele esandleni kwesokunxele nakwesokudla, ahlanganiswe futhi ahlanganiswe ngokuxhuma izinduku eziphambanayo.

Idizayini ye-Flat Spiral's mesh eshintshashintshayo isiza ekunciphiseni izinkinga zokulandelela ezibangelwa ukuchezukela kwebhande ohlangothini olulodwa.Izimbobo ezincane ezikhona ekwakhiweni kwebhande zinikeza abasebenzisi bokugcina indawo yokudlulisa eyisicaba elungele imikhiqizo ejwayele ukushibilika kumadizayini anezikhala avulekile.

Ibhande lingahlinzekwa ngonqenqema olushiselwe, olunezitebhisi noma lwehuku futhi lisetshenziswa ekuhlelweni kokuhambisa okuqhutshwa ukungqubuzana.I-Flat Spiralcan nayo inganikezwa imiphetho yeketango lapho ukumiswa kwedrayivu evumayo kuyadingeka.I-Flat Spiral ivamise ukunikezwa eBangeni 304 Insimbi Engagqwali, nokho, ezinye izinto zokwakha ziyatholakala uma uzicela.

Ukutholakala komphetho

I-Laddered Edge (LD) - inemeshi kuphela

Intambo enqamulayo enezitebhisi ukuphela konqenqema okujwayelekile kwamabhande e-Flat Spiral.Unqenqema lwebhande lubushelelezi futhi luvumela ukuguquguquka okwengeziwe konqenqema lwebhande.Kuvame ukusetshenziswa lapho ama-welds engafiseleki ekusetshenzisweni.Isebenza kahle futhi ezinhlelweni zokushisa okuphezulu njengoba unqenqema olunezitebhisi lungekho ngaphansi kobunzima bokusebenza olusetshenziswayo futhi ngenxa yalokho akulula ukuphuka.

I-Hook Edge (H) - inemeshi kuphela

Okungajwayelekile kakhulu kunohlobo lwamanqe anezitebhisi, unqenqema lwehuku luvame ukusetshenziswa lapho ama-welds engafuneki ekusetshenzisweni.Kubuye kube inketho kuzicelo lapho izinsiza zokushisela zingatholakali.Unqenqema lwebhande lubushelelezi futhi luvumela ukuguquguquka konqenqema lwebhande.

I-Welded Edge (W) - inezikhala kuphela

Lokhu kuhlelwa akuvamile kakhulu kunesitebhisi noma unqenqema lwehhuku njengoba kukhona ukuguquguquka okuncishisiwe phakathi kwekhoyili nentambo enqamulayo emaphethelweni.Uma kuhlangene kokubili ikhoyili nezintambo eziphambanayo azikho iziphetho zezintambo ezisikiwe.

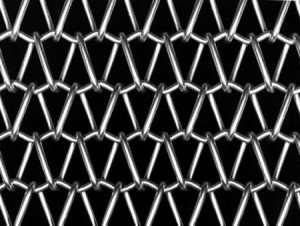

I-Chain Edge Driven Mesh

Kanye namaphethelo anezikhala angenhla la mameshi angashayelwa ngamaketango aseceleni kusetshenziswa izinti eziphambanayo ezitholakala kumakhoyili anezikhala bese kuthi amaketango emaphethelweni emanetha.Izinhlobo ze-cross rod finish ingaphandle leketango elisemaceleni zimi kanje:

Ngewashi elishiselwe

Lesi isitayela esivame kakhulu nesongayo sokuqeda ebhandeni lonqenqema lweketango futhi sihlanganisa inetha elimaphakathi elithwalwa ngohlelo kusetshenziswa amaketango asemaphethelweni anama-cross rods kuwo womabili amaketanga anonqenqema namaketango.Kuye ngokuthi i-mesh cross wire pitch i-cross rods ingase ithathe indawo ye-cross wire ye-basic mesh.Izinti eziphambanayo ziqedwa emaphethelweni eketango langaphandle ngewasha elishiselwe.

Ngephinikhodi newasha

Nakuba lolu hlobo lokuhlanganisa lungonga kangako luvumela ikhasimende noma izisebenzi zesevisi amandla okushintsha amaketanga onqenqema lokushayela lapho anezikhala nezinduku kusasebenza.Ukuhlanganiswa kuhlanganisa inetha elimaphakathi elithwalwa ngohlelo ngokusebenzisa amaketango asemaphethelweni anama-rod anqamula umthwali kuwo womabili amaketanga anezikhala nasemphethweni.Ama-cross rods aqedwa ngaphandle ngembobo ebhoboziwe ukuze kufakwe iwasha nephinikhodi.Iphinde ivumele ukushintshwa kwezingxenye zebhande ngaphandle kwesidingo sokugaya amakhanda enduku bese weld emuva ndawonye.

QAPHELA: Ukuze izinti zizinze ngobubanzi obukhulu ukuze kuboshwe iketango kuyinto evamile, lapho kunokwenzeka khona, ukuhlinzeka ngeziphambano ezijikisiwe ukuze zidlule emaketangeni asemaphethelweni.

Ezinye izitayela ezahlukahlukene zokuqedwa konqenqema lwe-chain

Lokhu kubandakanya:-

a.Induku eyisiphambano eshiselwe shayela ephinini elingenalutho leketango elisemaceleni.Lokhu akulona izinga elincanyelwayo kodwa kungase kudingeke lapho ububanzi phakathi kwamafreyimu aseceleni esithumeli nezinye izingxenye zesakhiwo budala umkhawulo lapho “iwasha eshiselwe” noma “i-washer & pin ye-cotter” ingakwazi ukusetshenziswa khona.

b.Induku ephambanayo eshiselwe ibhobozwe embotsheni engaphakathi yeketango le-roller conveyor.

Ngokuvamile amabhande aqhutshwa ngamaketango atholakala ngezitayela ezi-2 zeketango elisemaphethelweni: -

I-Transmission Chain - ine-roller encane

I-chain edge side plate ingasekelwa kuhlaka oluseceleni lwe-engeli, noma ngomzila wesitimela owenziwe iphrofayili ukuze uhambe phakathi kwamapuleti aseceleni kanye nokusekela kurola.Kungenjalo ingasebenza ngaphandle kosekelo lweketanga lapho inetha lisekelwa eduze konqenqema lweketango.

I-Conveyor Roller Chain -inerola elikhulu.

Lolu nqenqema lweketango lungasekelwa emgqeni wokugqoka we-engeli eyisicaba kanye nerola yeketango ezungeza ngokukhululekile kubude besithumeli.Isenzo se-roller seketango sinciphisa ukuguga kweketango futhi sinciphisa ukungqubuzana kokusebenza kuleli phuzu.

Izindlela zeDrayivu

I-Friction Driven

Uhlobo oluvame kakhulu lokushayela i-plain steel parallel driven roller system.Lolu hlelo luncike ekuxhumaneni okungqubuzanayo phakathi kwebhande nerola ukuze kuqinisekiswe ukushayela kwebhande.

Ukwehluka kwalolu hlobo lokushayela kuhlanganisa ukuxega kwe-roller ngezinto ezifana nerabha, i-friction brake lining (izinga lokushisa eliphezulu), njll. Ukusetshenziswa kwezinto ezinjalo zokushayisana kuvumela ukuthi kunciphe ukushuba kokushayela ebhandeni, ngaleyo ndlela kukhule. impilo ewusizo yebhande.

I-Chain Edge Iqhutshwa

Ngalokhu kuhlanganiswa kwebhande i-cross wire pitch ye-belt mesh ikhiqizwa ukuze kuqinisekiswe ukuthi unqenqema lweketango luyindawo yokushayela futhi i-mesh yebhande idonswa kumjikelezo ngamaketanga.

Ukutholakala Kwezinto Ezijwayelekile (Imeshi Kuphela):

| Okubalulekile | Izinga Lokushisa Eliphezulu Lokusebenza Kwezintambo °C |

| Insimbi Yekhabhoni (40/45) | 550 |

| Insimbi Eqinile Eqinile | 400 |

| I-Chrome Molybdenum (3% Chrome) | 700 |

| I-304 Stainless Steel (1.4301) | 750 |

| I-321 Stainless Steel (1.4541) | 750 |

| I-316 Stainless Steel (1.4401) | 800 |

| 316L Insimbi Engagqwali (1.4404) | 800 |

| I-314 Stainless Steel (1.4841) | 1120 (Gwema ukusebenzisa ku-800-900°C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| I-80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |