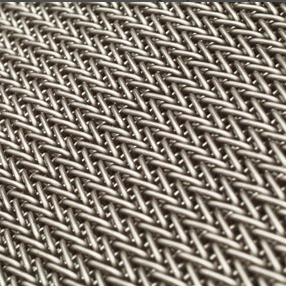

Kwaziwa nangokuthi 'i-Compound Balanced' ibhande

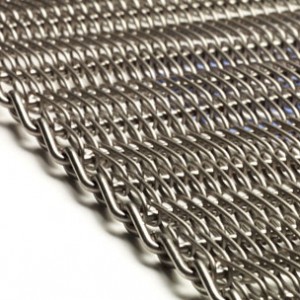

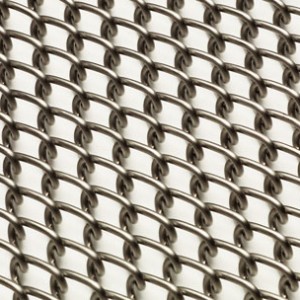

Amabhande e-Cordweave eNkampani ye-Wire Belt anikezela ngezikhala ezisondele kakhulu futhi eziyisicaba zohlelo lokusebenza lapho kuhanjiswa khona izinto ezincane kakhulu.I-Cordweave futhi ihlinzeka ngokudluliswa kokushisa okufanayo kulo lonke ibhande ngenxa yokuminyana kwayo okuphezulu kanye nendawo yokuthwala ebushelelezi.Lezi zici zenza i-Cordweave ibe inketho ethandwayo ezinhlelweni eziningi ezihlukahlukene, kusukela ekubhakeni amabhisikidi kuya ekuhleleni izingxenye ezincane zemishini.

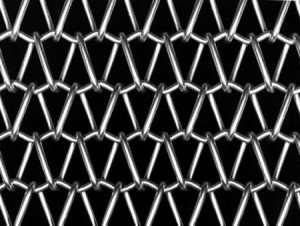

Eyaziwa futhi embonini ngokuthi ibhande le-“Compound Balanced (CB)”, ibhande le-Cordweave empeleni liyibhande eli-Balanced Spiral elinama-spiral amaningi nama-cross rod per pitch, okwenza ngempumelelo “ibhande ngaphakathi kwebhande”.Lesi sakhiwo esiyinhlanganisela sivala izimbobo ngaphakathi kwebhande, sinikeze i-Cordweave isici sayo sokuminyana okuphezulu kanye nendawo eyisicaba.

Ngokunikeza indawo yokuthwala eyisicaba enendawo encane evulekile, i-Cordweave iyinketho ethandwayo yezinhlelo zokusebenza ezihlukahlukene njengokuhlanganisa ibhodlela ekubhakeni imikhiqizo emincane yokudla okulula.I-Cordweave idume kakhulu ekubhakeni njengoba ukwakhiwa kwayo okuminyana kakhulu kuqinisekisa ukudluliswa kokushisa okufanayo kuya emkhiqizweni.

I-Cordweave ivamise ukunikezwa ku-Grade 304 Insimbi Engagqwali kanye nensimbi ye-carbon ephezulu;nokho ezinye izinto ziyatholakala uma uzicela.Idrayivu isetshenziswa ngokusetshenziswa kwamarola okushayisana, okuhlukile konqenqema olutholakala ngesicelo esikhethekile.Ngezinhlelo zokusebenza ezidinga ukuphakama noma ukuhlukaniswa komkhiqizo, i-Cordweave ingahlinzekwa ngezindiza ezinqamulayo kanye namapuleti aseceleni aqondene nezidingo zakho.

Ezinye Izicelo Ezikhethekile Zesitayela Sebhande

- Ukuphatha Irayisi

- Ama-Swarf Conveyors

- Ukwelashwa Kokushisa Kwezinsimbi Ezincane

- Ikhethini lesithando somlilo

- I-Sintering ye-Powdered Metal Components

- Electro-Plating

- Amathebula Okunqwabelana

- Ukomisa Imbewu

I-Standard Cordweave (CORD)

Ukuhlanganiswa okujwayelekile kuhlanganisa amakhoyili ashintshanayo esandla sobunxele nesokudla ikhoyili ngayinye ixhumene nelandelayo ngenani lezintambo eziphambanayo kukhoyili ngayinye.Ukwethulwa kwezintambo eziphambanayo ezingeziwe kukhoyili ngayinye kuvumela ukuvaleleka kwamakhoyili aseduze kokubili ububanzi nobude.Ngokuhlanganisa amabhande e-Cordweave axegayo kungase kudingeke ukuba unikeze izintambo eziphambanayo ngendlela ecijile (njengoba ngamabhande e-Balanced Spiral weave) ukuze kuqinisekwe ukuthi izintambo zekhoyili zinezidleke.Kuleli fomethi zombili izintambo zekhoyili nezawela ziyingxenye eyindilinga.

Ukuze uthole indlela yokuhlonza ikhodi yebhande

Ezinye izindlela ze-Flat Wire Coil

Imininingwane ye-mesh iyatholakala futhi ngezintambo zekhoyili ezenziwe kusetshenziswa intambo eyisicaba.Lezi zitayela ziwusizo kakhulu ukuthola indawo engaphezulu lapho uphatha imikhiqizo yendawo eyisisekelo.Lapho ubona ucingo lwekhoyili kubalulekile ukuqinisekisa ubukhulu besigaba esiphambanayo.

Ukutholakala komphetho

I-Welded Edge

Ngenxa yokuvaleka kwe-meshing yakho kokubili i-crimp ne-cross wire, i-welded uhlobo olujwayelekile olutholakalayo lokuqedwa konqenqema.

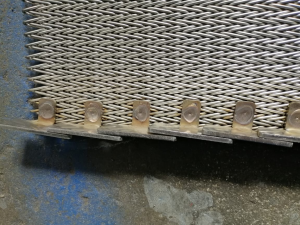

I-Chain Edge Driven Specialty Mesh

Lesi sitayela sebhande sihlanganisa i-mesh eyisisekelo engenhla kodwa ifakwe ngokukhethekile emaphethelweni eketango ukuze kuqinisekiswe ukushayela nokulandelelwa kahle.Ngalo mhlangano uchungechunge lwama-edge luyi-drive medium ne-mesh edonswa kumjikelezo.Inqunyelwe kuhlu oluncane lwezinketho ze-mesh futhi ezikhathini eziningi ihlanganisa amakhoyili anwetshiwe endaweni yokuhlanganisa ye-cross rod.Ngenxa yendlela yokuhlanganisa leli bhande alikho ngokomnotho kunesitayela esiqhutshwa yi-plain friction.

Izindlela zeDrayivu

I-Friction Driven

I-Friction Drive Circuit elula

Uhlobo oluvame kakhulu lokushayela i-plain steel parallel driven roller system.Lolu hlelo luncike ekuxhumaneni okungqubuzanayo phakathi kwebhande nerola ukuze kuqinisekiswe ukushayela kwebhande.

Ukwehluka kwalolu hlobo lokushayela kuhlanganisa ukuxega kwe-roller ngezinto ezifana nerabha, i-friction brake lining (izinga lokushisa eliphezulu), njll. Ukusetshenziswa kwezinto ezinjalo zokushayisana kuvumela ukuthi kunciphe ukushuba kokushayela ebhandeni, ngaleyo ndlela kukhule. impilo ewusizo yebhande.

I-Friction Drive Snub Pulley Circuit

I-Special Chain Edge Drive

Le ndlela isebenzisa unqenqema olukhethekile lwe-mesh enamaketanga ashayelwa ama-sprocket e-chain atholakala ku-drive kanye nama-shaft angenalutho ukuze aqondaniswe nalawa maketango.Amakhoyili akhethekile amade angase adingeke ezindaweni lapho okuphambana khona izintambo ngokungezwa kwezintambo zokugcwalisa uma umkhiqizo uba mncane - bheka isithombe ngezansi.

Imininingwane Etholakalayo

Ithebula elingezansi liyisiqephu samameshi atholakalayo futhi libonisa imininingwane evame kakhulu:

| Ikhodi yokucaciswa. | I-Coil Pitch Ngaphesheya Kobubanzi | I-Coil Wire Dia. | I-Cross Wire Pitch Down Length | I-Cross Wire Dia. | Inombolo Yezintambo Eziphambanayo ikhoyili ngayinye. |

| I-CORD3 | 5.08 | 1.22 | 3.05 | 1.22 | 3 |

| I-CORD4 | 11.29 | 2.03 | 4.35 | 2.03 | 4 |

| I-CORD4 | 10.16 | 2.03 | 5.08 | 2.64 | 4 |

| I-CORD4 | 4.24 | 0.91 | 2.24 | 1.22 | 4 |

| I-CORD4 | 8.47 | 1.63 | 3.63 | 1.63 | 4 |

| I-CORD4 | 6.35 | 1.22 | 2.82 | 1.22 | 4 |

| I-CORD5 | 8.71 | 1.6 x 1.3* | 3.39 | 1.63 | 5 |

Zonke izilinganiso ngamamilimitha (mm).

*Usayizi omncane.

Ukucaciswa okwengeziwe kuyatholakala.Sicela uthinte Onjiniyela bethu Bezentengiselwano ukuze uthole ulwazi olwengeziwe.

Ezinye Izicelo Ezikhethekile Zesitayela Sebhande

- Ukuphatha Irayisi

- Ama-Swarf Conveyors

- Ukwelashwa Kokushisa Kwezinsimbi Ezincane

- Ikhethini lesithando somlilo

- I-Sintering ye-Powdered Metal Components

- Electro-Plating

- Amathebula Okunqwabelana

- Ukomisa Imbewu

Ukutholakala Kwezinto Ezijwayelekile (Imeshi Kuphela)

| Okubalulekile | Izinga Lokushisa Eliphezulu Lokusebenza Kwezintambo °C |

| Insimbi Yekhabhoni (40/45) | 550 |

| Insimbi Eqinile Eqinile | 400 |

| I-Chrome Molybdenum (3% Chrome) | 700 |

| I-304 Stainless Steel (1.4301) | 750 |

| I-321 Stainless Steel (1.4541) | 750 |

| I-316 Stainless Steel (1.4401) | 800 |

| 316L Insimbi Engagqwali (1.4404) | 800 |

| I-314 Stainless Steel (1.4841) | 1120 (Gwema ukusebenzisa ku-800-900°C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| I-80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |

Ngaphambi kokukhetha izicelo zokushisa okuphezulu thintana Nonjiniyela Bezentengiselwano bethu ukuze uthole ibanga elifaneleka kakhulu lezintambo zohlelo lokusebenza njengoba amandla ezintambo ehla emazingeni okushisa aphakeme.