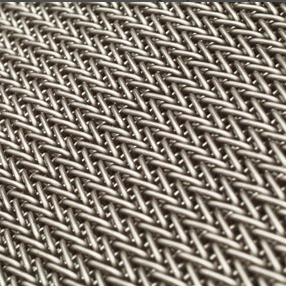

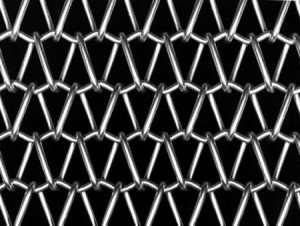

I-Chain Link ifaka idizayini elula, lapho amakhoyili ayindilinga alandelanayo elukwa khona ukuze akhe inetha elivulekile.I-Chain Link ingahlinzekwa ngemiphetho noma ihlanganiswe noma ishiselwe.

Ngokugcina idizayini yebhande ilula kodwa isebenza, i-Wire Belt Chain Link yenkampani inikeza abasebenzisi bokugcina isisombululo sezomnotho nesilula sezinhlelo zokusebenza zokudlulisa umthwalo ophansi.Indawo enkulu evulekile etholakala ekwakhiweni kwe-Chain Link futhi ikwenza kube ukukhetha okudumile kokumisa nokupholisa lapho ukugeleza kwebhande kubaluleke kakhulu.

I-Chain Link inganikezwa namaphaneli abheke kwesokunxele nakwesokudla ashintshanayo ukuze kuliwe nanoma yiziphi izinkinga zokulandelela ezibangelwa iphethini yekhoyili.Iphinde itholakale njenge-Rod Reinforced Chain Link, lapho izinti eziphambanayo zifakwa phakathi kobubanzi bebhande ukuze kwandiswe umthamo wawo wonke womthwalo.I-Chain Link ivame ukunikezwa eBangeni lama-304 Lensimbi Engagqwali, nakuba amanye amabanga ensimbi etholakala uma ecelwa.

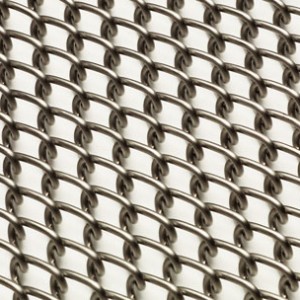

I-Standard Chain Link (CL)

I-assembly iqukethe amakhoyili angaqondile kanye nekhoyili ngayinye exhumanisa nelandelayo.Uma isetshenziswa njengebhande eliqhutshwa ukungqubuzana umhlangano ungase ube nezingxenye ezishintshayo zamaphaneli ahlanganiswe kwesokunxele bese kwesokudla.Iphaneli yebhande ngalinye lixhunywe kuphaneli yokuluka yesandla elandelayo ngocingo oludlulayo - bheka ngezansi.Ukufakwa kwebhande kwebhande ngezingxenye zekhoyili yesandla sokunxele nesokudla kusiza ekudambiseni amabhande kuwo wonke ama-circuit roller nezisekelo zamabhande.Amabhande amaningi aqhutshwa yi-friction nokho awafakwe iphaneli ngale ndlela futhi ancike esisindweni sawo kanye nesistimu yokulandelela i-conveyor ukuze kuqinisekiswe ukusebenza okuqondile kwebhande.

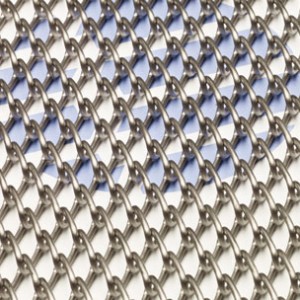

I-Rod Reinforced Chain Link (CLR)

Ukwengeza amandla kanye nokusimama kwebhande ebhandeni amakhoyili ahlanganayo axhunywa ngocingo oludlulayo.Lokhu ngocingo kuqedwa emaphethelweni ngezitayela ezehlukene ezihlanganisa ezishiselwe, ezifakwe iledi, eziguquliwe nezishiselwe futhi zicindezelwe futhi zishiselwe.Uma ubuza sicela uthumele isithombe noma umdwebo wonqenqema lwebhande.Ukuhlanganiswa okufanayo kwamaphaneli njengoba kuchazwe ngenhla kungase kudingeke uma kusetshenziswe kuphela njengebhande eliqhutshwa ukungqubuzana.

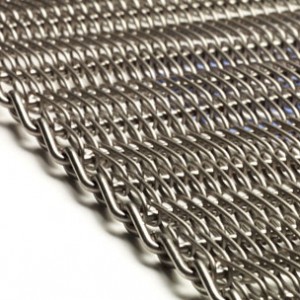

I-Rod Reinforced Chain Link - i-Duplex (CLR-Duplex)

Ukwengeza amandla amaningi ebhande futhi unciphise indawo evulekile ke inguqulo ye-duplex yenduku evamile eqinisiwe iyatholakala.I-assembly iqukethe amakhoyili amabili ajwayelekile ahlanganayo endaweni ngayinye.

I-Standard Chain Link (CL)

Lokhu kuklanyelwe ukuhambisana nezidingo zamakhasimende kodwa ngokuvamile kuyatholakala kuma-coil lateral wire pitches ukusuka ku-5.08mm kuya ku-25.4mm, kuhlanganiswe nezinhlobonhlobo zamadayamitha ezintambo kanye nama-longitudinal pitches ukuze avumelane nohlelo.

I-Rod Reinforced Chain Link (CLR)

| I-Lateral Coil Pitch (mm) | I-Coil Wire Diameter (mm) | I-Longitudinal Cross Wire Pitch (mm) | I-Cross Wire Diameter (mm) |

| 16.93/15.24 | 2.03 | 16.93/19.05 | 2.64 |

| 2.64 | 2.95 | ||

| 2.95 | 3.25 | ||

| 3.25 | 4.06 |

I-Rod Reinforced Chain Link - i-Duplex (CLR-D)

| I-Lateral Coil Pitch (mm) | I-Coil Wire Diameter (mm) | I-Longitudinal Cross Wire Pitch (mm) | I-Cross Wire Diameter (mm) |

| 8.47 | 2.03 | 16.93/19.05 | 2.64 |

| 2.64 | 2.95 | ||

| 2.95 | 3.25 | ||

| 3.25 | 4.06 | ||

| 5.08 | 2.03 | 10.16 | 2.64 |

Zonke izilinganiso zingamamilimitha (mm) futhi zingaphansi kokubekezelelwa kokukhiqiza kwe-Wire Belt Company.

Ukutholakala komphetho

I-Welded Edge (W) - inezikhala kuphela ngaphandle kwezinduku zokuqinisa

Emaphethelweni ebhande izintambo zekhoyili ziboshwe ndawonye futhi zishiselwe.Lolu hlobo lokuqedwa konqenqema luvumela ukuphela okushelelezi onqenqemeni lwebhande futhi inguqulo yezomnotho kakhulu yalesi sitayela sebhande.

I-Knuckled Edge (K) - inezikhala kuphela ngaphandle kwezinduku zokuqinisa

Isiphetho sentambo yekhoyili ngayinye igotshwa yabuyela esimweni sika-'U' bese ihlangana nekhoyili eseduze.Ifomu elithi 'U' libe selivalwa ngokuphephile ukuze kwakheke isixhumanisi esihlala njalo ngekhoyili elandelayo.Lokhu kwakheka futhi kuvumela ukuguquguquka okukhulu kwemiphetho yebhande futhi kunciphise ukucindezeleka okwakhiwa kulezi zikhundla.

Ukuqedwa konqenqema kuya kunduku evamile eqinisiwe (inenetha kuphela) Amabhande Okuxhumanisa i-Chain

Lokhu kubandakanya okulandelayo:

I-Welded Chain Link Rod Iqinisiwe (CLR-W – IN/OUT).Ama-cross rods anobude obubili obuhlukene benduku ukubhekelela iphethini yonqenqema yokuxhuma ikhoyili.Ama-cross rods ashiselwe kumakhoyili ngendlela yokuhlanganisa ethi “In – Out”.

I-Welded Chain Link Rod Reinforced (CLR-W-IN LINE).Onke ama-cross rods anobude obufanayo kanti enye inhlonhlo yekhoyili icindezelwe ukuze kufinyelelwe esiphethweni sokuthi “Kulayini”.

I-Chain Link Rod Iqiniswe Iphinikhodi egobile enemiphetho eshiselwe (CLR-W-BENT-PIN).

Ngalo mhlangano izinduku eziphambanayo zigotshwa ekugcineni ngo-90° futhi zishiselwe ekugcineni kocingo lwekhoyili olwandulele.Ukuze uqondanise imiphetho yebhande, yonke enye ikhoyili iyacindezelwa emaphethelweni ngaphambi kokushisela.

I-Knuckled Chain Link 'U' Cross Rod Reinforced (CLR-K/U).

Ngalesi sitayela sokuhlanganisa ama-cross rods akhiwa njengamapheya ku-hairclip style 'U' inhlangano yokwakheka.Izinti eziphambanayo ezimise okuka-'U' zigcinwa endaweni kusetshenziswa imiphetho yekhoyili egoqiwe futhi ishuthekwa ngokushintshana ukusuka nhlangothi zombili lapho kuhlanganisa ibhande.

Njengenketho yalesi sakhiwo sonqenqema intambo yomsila emaphethelweni ekhoyili eknuckled ingaphinde iboshwe ibuyele kukhoyili (CLR-K/U/W).

Ukuqedwa konqenqema kuya ku-duplex eqinisiwe (inenetha kuphela) Amabhande Okuxhumanisa i-Chain

I-Welded Duplex Chain Link (CLR-W-Duplex).Ukuhlanganiswa kuqukethe amapheya ezintambo zekhoyili eziphothene ezineziphetho zekhoyili ezishiselwe ngqo ezintanjeni eziphambanayo ezinobude obulinganayo emaphethelweni.

Isixhumanisi Se-Duplex Chain Eguquliwe/Esishukiwe (CLR-K/H-Duplex).

I-Welded Duplex Chain Link (CLR-W-Duplex).Ukuhlanganiswa kuqukethe amapheya ezintambo zekhoyili eziphothene ezineziphetho zekhoyili ezishiselwe ngqo ezintanjeni eziphambanayo ezinobude obulinganayo emaphethelweni.

Isixhumanisi Se-Duplex Chain Eguquliwe/Esishukiwe (CLR-K/H-Duplex).

I-Chain Edge Driven Mesh:

Kanye namaphethelo anezikhala angenhla la mameshi angashayelwa ngamaketango aseceleni kusetshenziswa izinti eziphambanayo ezitholakala kumakhoyili anezikhala bese kuthi ngamaketango emaphethelweni emanetha.Izinhlobo ze-cross rod finish ingaphandle leketango elisemaceleni zimi kanje:

Ngewashi elishiselwe

Lesi isitayela esivame kakhulu nesongayo sokuqeda ebhandeni lonqenqema lweketango futhi sihlanganisa inetha elimaphakathi elithwalwa ngohlelo kusetshenziswa amaketango asemaphethelweni anama-cross rods kuwo womabili amaketanga anonqenqema namaketango.Kuye ngokuthi i-mesh cross wire pitch i-cross rods ingase ithathe indawo ye-cross wire ye-basic mesh.Izinti eziphambanayo ziqedwa emaphethelweni eketango langaphandle ngewasha elishiselwe

Nge-Cotter Pin & Washer

Nakuba lolu hlobo lokuhlanganisa lungonga kangako luvumela ikhasimende noma izisebenzi zesevisi amandla okushintsha amaketanga onqenqema lokushayela lapho anezikhala nezinduku kusasebenza.Ukuhlanganiswa kuhlanganisa inetha elimaphakathi elithwalwa ngohlelo ngokusebenzisa amaketango asemaphethelweni anama-rod anqamula umthwali kuwo womabili amaketanga anezikhala nasemphethweni.Ama-cross rods aqedwa ngaphandle ngembobo ebhoboziwe ukuze kufakwe iwasha nephinikhodi.Iphinde ivumele ukushintshwa kwezingxenye zebhande ngaphandle kwesidingo sokugaya amakhanda enduku bese weld emuva ndawonye.

QAPHELA: Ukuze izinti zizinze ngobubanzi obukhulu ukuze kuboshwe iketango, kuyinto evamile, lapho kungenzeka khona, ukunikeza izinti eziphambanayo ezijikisiwe ukuze zidlule ephinini elingenalutho lamaketango onqenqema.

Ezinye izitayela ezahlukahlukene zokuqedwa konqenqema lwe-chain

Lokhu kubandakanya:

a.I-cross rod eshiselwe iphinifa elingenalutho leketango elisemaceleni.Lokhu akulona izinga elincanyelwayo kodwa kungase kudingeke lapho ububanzi phakathi kwamafreyimu aseceleni esithumeli nezinye izingxenye zesakhiwo budala umkhawulo lapho “iwasha eshiselwe” noma “i-washer & pin ye-cotter” ingakwazi ukusetshenziswa khona.

b.Induku yesiphambano eshiselwe embotsheni ebhoboziwe kumapuleti angaphakathi eketango le-roller conveyor.

Ngokuvamile amabhande aqhutshwa ngamaketango atholakala ngezitayela ezi-2 zeketango elisemaphethelweni: -

I-Transmission Chain - ine-roller encane

I-chain edge side plate ingasekelwa kuhlaka oluseceleni lwe-engeli, noma ngomzila wesitimela owenziwe iphrofayili ukuze uhambe phakathi kwamapuleti aseceleni kanye nokusekela kurola.Kungenjalo ingasebenza ngaphandle kosekelo lweketanga lapho inetha lisekelwa eduze konqenqema lweketango.

I-Conveyor Roller Chain -inerola elikhulu.

Lolu nqenqema lweketango lungasekelwa emgqeni wokugqoka we-engeli eyisicaba kanye nerola yeketango ezungeza ngokukhululekile kubude besithumeli.Isenzo se-roller seketango sinciphisa ukuguga kweketango futhi sinciphisa ukungqubuzana kokusebenza kuleli phuzu.

Izindlela zeDrayivu

I-Friction Driven

Uhlobo oluvame kakhulu lokushayela i-plain steel parallel driven roller system.Lolu hlelo luncike ekuxhumaneni okungqubuzanayo phakathi kwebhande nerola ukuze kuqinisekiswe ukushayela kwebhande.

Ukwehluka kwalolu hlobo lokushayela kuhlanganisa ukuxega kwe-roller ngezinto ezifana nerabha, i-friction brake lining (izinga lokushisa eliphezulu), njll. Ukusetshenziswa kwezinto ezinjalo zokushayisana kuvumela ukuthi kunciphe ukushuba kokushayela ebhandeni, ngaleyo ndlela kukhule. impilo ewusizo yebhande.

I-Chain Edge Iqhutshwa

Ngalokhu kuhlanganiswa kwebhande i-cross wire pitch ye-belt mesh ikhiqizwa ukuze kuqinisekiswe ukuthi unqenqema lweketango luyindawo yokushayela futhi i-mesh yebhande idonswa kumjikelezo ngamaketanga.

Ukutholakala Kwezinto Ezijwayelekile (Imeshi Kuphela)

| Okubalulekile | Izinga Lokushisa Eliphezulu Lokusebenza Kwezintambo °C |

| Insimbi Yekhabhoni (40/45) | 550 |

| Insimbi Eqinile Eqinile | 400 |

| I-Chrome Molybdenum (3% Chrome) | 700 |

| I-304 Stainless Steel (1.4301) | 750 |

| I-321 Stainless Steel (1.4541) | 750 |

| I-316 Stainless Steel (1.4401) | 800 |

| 316L Insimbi Engagqwali (1.4404) | 800 |

| I-314 Stainless Steel (1.4841) | 1120 (Gwema ukusebenzisa ku-800-900°C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| I-80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |

Ngaphambi kokukhetha izicelo zokushisa okuphezulu thintana Nonjiniyela Bezentengiselwano bethu ukuze uthole ibanga elifaneleka kakhulu lezintambo zohlelo lokusebenza njengoba amandla ezintambo ehla emazingeni okushisa aphakeme.