isicelo

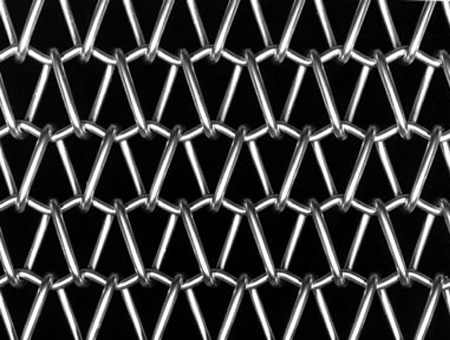

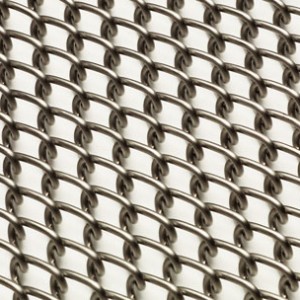

I-Balanced Spiral mesh inomklamo olula kodwa osebenzayo, owakhiwe ngamakhoyili asontekile ashintshanayo kwesokunxele nakwesokudla.Lawa makhoyili abanjwa endaweni yawo ngokuxhuma ama-crimp rods ahamba phakathi kobubanzi bebhande.Imiphetho yebhande inganikezwa noma i-welded noma nge-knuckled selvedge.

I-Balanced Spiral izuza izici zayo zokulandela umkhondo ezinhle kakhulu ngokusebenzisa iphethini eshintshanayo evimbela ibhande ukuthi lidonsele ohlangothini olulodwa.Ukunyakaza kwe-lateral ngaphakathi kwebhande kuncishiswa ngokusetshenziswa kwezinduku ezicijile ngokukhethekile ezibamba ikhoyili ngayinye e-spiral endaweni yayo.

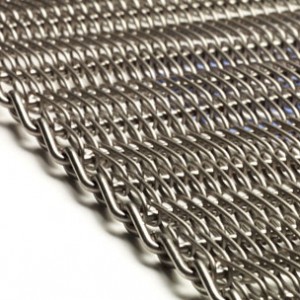

I-Balanced Spiral ivamise ukunikezwa njengebhande le-friction-drive;kodwa-ke amameshi athile anganikezwa njenge-Positive-Drive, okuvumela ama-sprockets ukuthi ahlanganyele ne-mesh yamabhande.Kungenjalo, singahlinzeka nge-Balanced Spiral nge-chain edges yezinhlelo zokusebenza zokulayisha okuphezulu.

I-Cross-Flights kanye nama-Side Plates ayatholakala ngezinhlelo zokusebenza ezithambekele noma izidingo zokuhlukaniswa komkhiqizo.I-Wire Belt Company iphinde inikeze i-Double Balanced Spiral belting, ngezinhlelo zokusebenza ezinomthwalo ophakeme kakhulu kanye/noma ngemikhiqizo edinga indawo evulekile encane kunaleyo engenzeka ngamabhande athandelayo abhalansile.

I-Standard Balanced Spiral (BS)

Ukuhlanganiswa kuqukethe amakhoyili ashintshayo esandla sokunxele nesokudla ikhoyili ngayinye ixhumene nelandelayo ngokusebenzisa intambo enqamulayo.

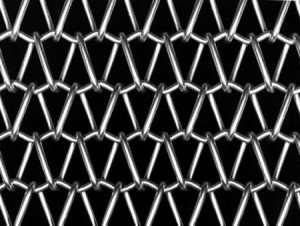

I-Double Balanced Spiral (DBS)

I-double balanced assembly iyafana ne-standard balanced spiral kodwa isebenzisa amakhoyili amakhoyili we-handing intermeshing bese ixhuma ngentambo enqamulayo enamapheya axhumanisa amakhoyili esandla aphambene kwiphethini ephindayo phansi ngobude.Lesi sitayela sivumela ukuhlotshaniswa okuseduze kwamakhoyili ngobubanzi bokuphatha umkhiqizo omncane.

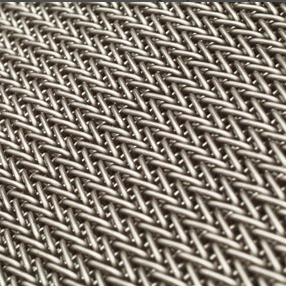

I-Improved Balanced Spiral (IBS)

Isakhiwo saleli bhande sifana ne-“Standard Balanced Spiral” kodwa sisebenzisa intambo enqamulayo eqondile enamakhoyili axhumayo awodwa kwiphethini ephindayo yesandla sokunxele/isandla sokudla phansi ngobude.Lo mhlangano uvumela ukuhlotshaniswa okuseduze kwamakhoyili owodwa ububanzi ukuze kubanjwe umkhiqizo omncane.

I-Double Balanced Spiral (IDBS) ethuthukisiwe

Isakhiwo saleli bhande sifana ne-“Double Balanced Spiral” kodwa sisebenzisa intambo eqondile enqamulayo enamakhoyili ahlanganayo aphindwe kabili ekuxhumaneni kwesandla ngasinye kusetshenziswa intambo enqamulayo eqondile ephethinini ephindayo yamakhoyili esandla sobunxele/kwesokudla eza phansi ngobude.Lo mhlangano uvumela ukuhlotshaniswa okuseduze kwamakhoyili ububanzi ukuze kubanjwe umkhiqizo omncane.

Ukutholakala komphetho

I-Welded Edge (W) - i-mesh kuphela

Lona ukuphela komkhawulo ovame kakhulu futhi ukonga.Ngokushisela ndawonye kokubili izintambo zekhoyili nezecrimp azikho iziphetho zezintambo ezisikiwe.

I-Laddered Edge (LD) - inemeshi kuphela

Okungajwayelekile kunonqenqema olushiselwe unqenqema olunezitebhisi luvame ukusetshenziswa lapho okushisela kungafiseleki khona ekufakweni.Kubuye kube inketho kuzicelo lapho izinsiza zokushisela zingatholakali.Unqenqema lwebhande nalo libushelelezi futhi livumela ukuguquguquka okwengeziwe konqenqema lwebhande.Isebenza kahle futhi ezinhlelweni zokushisa okuphezulu njengoba unqenqema olunezitebhisi lungekho ngaphansi kobunzima bokusebenza olusetshenziswayo futhi ngenxa yalokho akulula ukuphuka.Ngokuvamile lokhu kuqedwa konqenqema kutholakala kuphela kumameshi anentambo enkulu ngokuqhathaniswa ne-crimp ephansi ngobude.

I-Hook Edge (U) - inemeshi kuphela

Futhi okungavamile kakhulu kunohlobo lwe-welded edge i-hook edge ivame ukusetshenziswa lapho ama-welds engafuneki ekusetshenzisweni.Kubuye kube inketho kuzicelo lapho izinsiza zokushisela zingatholakali.Unqenqema lwebhande nalo libushelelezi futhi livumela ukuguquguquka okwengeziwe konqenqema lwebhande.Ngokuvamile lokhu kuqedwa konqenqema kutholakala kuphela kumameshi anentambo enkulu ngokuqhathaniswa ne-crimp wire phansi ngobude.

I-Chain Edge Driven Mesh

Kanye namaphethelo anezikhala angenhla la mameshi angashayelwa ngamaketango aseceleni kusetshenziswa izinti eziphambanayo ezitholakala kumakhoyili anezikhala bese kuthi ngamaketango emaphethelweni emanetha.Izinhlobo ze-cross rod finish ingaphandle leketango elisemaceleni zimi kanje:

Ngewashi elishiselwe

Lesi isitayela esivame kakhulu nesongayo sokuqeda ebhandeni lonqenqema lweketango futhi sihlanganisa inetha elimaphakathi elithwalwa ngohlelo kusetshenziswa amaketango asemaphethelweni anama-cross rods kuwo womabili amaketanga anonqenqema namaketango.Izinti eziphambanayo ziqedwa emaphethelweni eketango langaphandle ngewasha elishiselwe

Nge-Cotter Pin & Washer

Nakuba lolu hlobo lokuhlanganisa lungonga kangako luvumela ikhasimende noma izisebenzi zesevisi amandla okushintsha amaketanga onqenqema lokushayela lapho anezikhala nezinduku kusasebenza.Ukuhlanganiswa kuhlanganisa inetha elimaphakathi elithwalwa ngohlelo ngokusebenzisa amaketango asemaphethelweni anama-rod anqamula umthwali kuwo womabili amaketanga anezikhala nasemphethweni.Ama-cross rods aqedwa ngaphandle ngembobo ebhoboziwe ukuze kufakwe iwasha nephinikhodi.Iphinde ivumele ukushintshwa kwezingxenye zebhande ngaphandle kwesidingo sokugaya amakhanda enduku bese weld emuva ndawonye.

QAPHELA: Ukuze izinti zizinze ngobubanzi obukhulu ukuze kuboshwe iketango kuyinto evamile, lapho kunokwenzeka khona, ukuhlinzeka ngeziphambano ezijikisiwe ukuze zidlule emaketangeni asemaphethelweni.

Ezinye izitayela ezahlukahlukene zokuqedwa konqenqema lwe-chain zifaka:

- I-cross rod eshiselwe iphinifa elingenalutho leketango elisemaceleni.Lokhu akulona izinga elincanyelwayo kodwa kungase kudingeke lapho ububanzi phakathi kwamafreyimu aseceleni okuthutha nezinye izingxenye zesakhiwo budala umkhawulo lapho "iwasha eshiselwe" noma "i-washer & pin pin" ingakwazi ukusetshenziswa.

- Induku yesiphambano eshiselwe embotsheni ebhoboziwe kumapuleti angaphakathi eketango le-roller conveyor.

Ngokuvamile amabhande ashayelwa unqenqema lweketango njengoba kukhonjisiwe ngenhla atholakala ngezitayela ezi-2 zamaketango onqenqema:

I-Transmission Chain

Iketango lokudlulisela linerola elincane.Unqenqema lweketango lungasekelwa kumapuleti aseceleni eketango noma ngomzila wesitimela ofakwe iphrofayili ukuze uhambe phakathi kwamapuleti aseceleni nokusekelwa ku-roller noma ngaphandle kwalokho ngaphandle kokusekelwa lapho inetha lisekelwa eduze konqenqema.

I-Conveyor Roller Chain

I-Conveyor Roller Chain inerola elikhulu.Unqenqema lweketango lungabe selusekelwa emgqeni wokugqoka we-engeli eyisicaba kanye nerola yeketango ezungeza ngokukhululekile kubude besithumeli.

I-Positive Drive Belt Specifications

| Uhlobo lwe-Mesh | Ikhodi yokucaciswa | Ubugqinsi Bebhande Lobizo (mm) | I-Lateral Pitch of Coil wire(mm) | I-Coil Wire Dia.(mm) | Ubude be-Crimped Cross Wire Pitch phansi (mm) | I-Crimped Cross Wire Dia (mm) |

| I-BSW-PD | 18-16-16-16 | 7.7 | 16.94 | 1.63 | 19.05 | 1.63 |

| I-BSW-PD | 18-14-16-14 | 8.9 | 16.94 | 2.03 | 19.05 | 2.03 |

| I-BSW-PD | 30-17-24-17 | 7.3 | 10.16 | 1.42 | 12.7 | 1.42 |

| I-BSW-PD | 30-16-24-16 | 6.7 | 10.16 | 1.63 | 12.7 | 1.63 |

| I-BSW-PD | 42-18-36-18 | 6.0 | 7.26 | 1.22 | 8.47 | 1.22 |

| I-BSW-PD | 42-17-36-17 | 6.0 | 7.26 | 1.42 | 8.47 | 1.42 |

| I-BSW-PD | 42-16-36-16 | 6.4 | 7.26 | 1.63 | 8.47 | 1.63 |

| I-BSW-PD | 48-17-48-17 | 6.1 | 6.35 | 1.42 | 6.35 | 1.42 |

| I-BSW-PD | 48-16-48-16 | 6.4 | 6.35 | 1.63 | 6.35 | 1.63 |

| I-BSW-PD | 60-20-48-18 | 4.0 | 5.08 | 0.91 | 6.35 | 1.22 |

| I-BSW-PD | 60-18-48-18 | 5.2 | 5.08 | 1.22 | 6.35 | 1.22 |

| I-BSW-PD | 60-18-60-18 | 5.6 | 5.08 | 1.22 | 5.08 | 1.22 |

Yonke imininingwane inikezwa ngomphetho oshiselwe kuphela.

Ezinye izinhlelo zokusebenza eziyisipesheli zesitayela sebhande:

| I-Standard Material Availability (Mesh Kuphela) Material | Izinga Lokushisa Eliphezulu Lokusebenza Kwezintambo °C |

| Insimbi Yekhabhoni (40/45) | 550 |

| Insimbi Eqinile Eqinile | 400 |

| I-Chrome Molybdenum (3% Chrome) | 700 |

| I-304 Stainless Steel (1.4301) | 750 |

| I-321 Stainless Steel (1.4541) | 750 |

| I-316 Stainless Steel (1.4401) | 800 |

| 316L Insimbi Engagqwali (1.4404) | 800 |

| I-314 Stainless Steel (1.4841) | 1120 (Gwema ukusebenzisa ku-800-900°C) |

| 37/18 Nickel Chrome (1.4864) | 1120 |

| I-80/20 Nickel Chrome (2.4869) | 1150 |

| I-Inconel 600 (2.4816) | 1150 |

| I-Inconel 601 (2.4851) | 1150 |